After making the decision to move the coffee table into the flex room, we realized that what we really needed for the living room space was some sort of side table. With our L-shaped couch configuration, our first thought was to find something that could overlap the chaise. Something like this:

This style of table is not hard to find, but with prices ranging from $150-$400, DIY was starting to seem like a better alternative. I mean, how hard could it be?

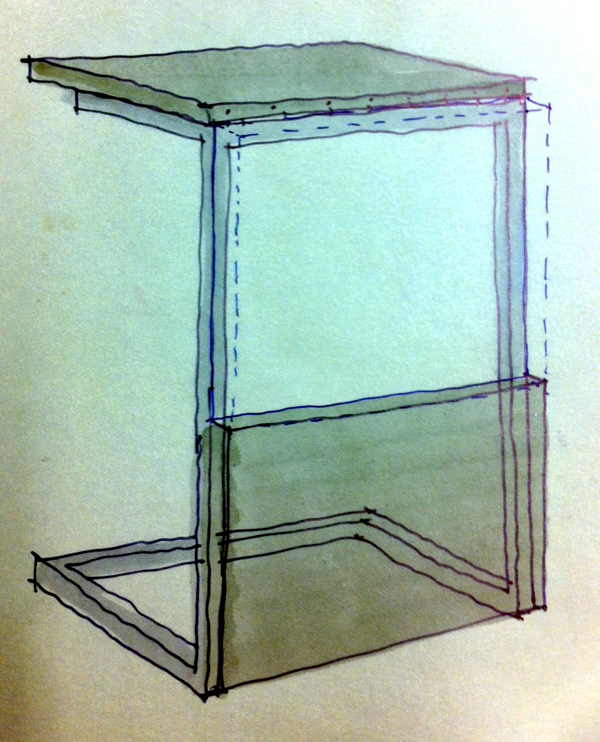

So a couple of weeks ago, after a few preliminary discussions and some back and forth e-mailing, we came up with an idea that’s a different spin on the ol’ C table. In a moment of simultaneous design vision, we realized that with one small move, what appeared to be one table could actually be two. To illustrate the idea, Kyle texted me this quick sketch (hence the funky colors):

Instead of a simple wood top fixed in place, we had the idea to use a piano hinge along one side so that the top could be flipped to the opposite side of the frame (as shown with the dashed blue line) and then the whole thing could be turned on its side, creating a coffee table of sorts.

Later that night we talked more about the design and ultimately ended up nixing the piano hinge (too fussy) and instead decided to use a simple friction fit method for the removable top.

So with the design settled on, it was time to build!

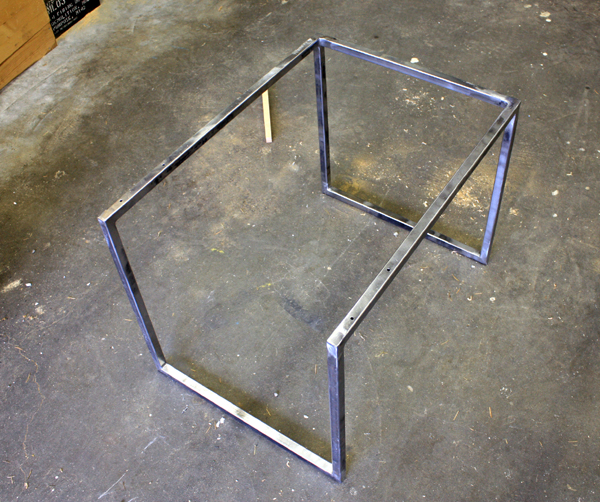

Kyle used 3/4″ tube steel that we had leftover from the loft ladder project. First he cut the pieces to size, then grinded them smooth to ensure a clean, mitered connection.

Next, he moved the pieces to the carport (aka the welding shop) and began setting up the frames for welding.

The key with welding is to have a solid work table that pieces can be securely clamped to.

[10 bonus points if you see Bailey in the above photo.]

To make sure that the corners were true 90 degree angles, he used this fancy Mag-Level…

After the welding was complete, Kyle used an angle grinder to clean up the welds.

The finished frame – a bit mottled but not a big deal since we planned on painting it.

[Newbie welder tip – we’ve found we have better results if you can either hide your welds (like with our planter boxes) or grind and paint them (like with our loft ladder). It’s a good way to get a nice end product without needing to go super high-end with your equipment.]

For the wood top, we wanted to use solid fir wood instead of a veneered plywood, so we decided to biscuit together three 1×8 boards.

After a quick dry fit to make sure everything was lining up, Kyle moved the frame down to the basement (aka the spray shop) to give it a few coats of our favorite black-gray automotive primer (the same thing we used on the loft ladder and barn door tracks).

The table top received a coat of Benite and a few coats of Satinthane. Here’s a shot of the underside that shows the wood strips that provide a snug friction fit into the frame.

To protect the paint finish and provide a slight reveal between the wood and the steel, Kyle added small plastic protectors at each corner.

And here’s the finished product – instead of making both pieces solid fir, we decided to instead face the larger table top with the same cork we used on our floors (we had some unfinished scraps leftover). Can you say giant coaster?

But wait, this isn’t just your run-of-the mill C table…

Nope, it’s a Transformer.

TRANSFORMER – coffee table in disguise!

(If you were a child in the ’80s…you’ll get that.)

That’s right, our lil’ table has a dual identity.

Over the years, we’ve learned that in a small home it’s crucial for pieces to serve multiple functions. Depending on our needs, we can change the configuration or location in just a few quick steps.

Oh and hey, it also works as a side table on the opposite side of the couch…

To get a flush transition between the two top pieces, we used 3/4″ fir for the fixed panel and 1/2″ fir (with approx. 1/4″ cork) for the removable panel. Kyle also did a very light sand at the cork for an eased edge.

It’s a bit tall, but in a pinch it could also double as a couch-based work station…

Finally, to test its durability we called in our feline expert:

The table is a prototype of sorts, but we like it. (As seen in the photos above, we’re also messing around with some more artwork ideas.) The “finishing touches” phase has been one of the most challenging for us, but with each bit of progress it starts to feel more and more like our home.

Beautiful AND clever.

SMARTIES.

(obvssss bailey is stuck inside, fixated on you guys and all “WHY DID THEY LEAVE MEEEE”)

The Felix series: yes.

This post has it all. Also, I love Daniel’s idea about the name. Of course you will have to come up with a Bailey. I am thinking a chair.

is there anything that kyle can’t build? if he were to ever give welding lessons, i’d be there in a heartbeat.

To echo Rick, when is Kyle going to write (or blog) “How to build everything”

After I saw your post about moving out the coffee table, I was thinking you would procure some sort of Eileen Gray table for beverages on the sofa. Your solution is amazing – very custom and so gorgeous. Have any furniture companies called yet asking to make reproductions? Who ever said we can’t have it all — Form AND Function! Cheers.

you all are so clever! i love the fact that you made the table so adaptable, plus it looks fantastic!

Brilliance. My co-worker and I were looking at this in awe…and just thinking how much the two of you have invested in tools. I’m inspired to take a welding class now. Great work again, Lauren and Kyle.

LOVE it! And not a unitasker either, which makes it extra special. Tres clever Zerbeys!

Wow. That table is ten kinds of awesome, but I can’t help but be distracted by your hanging plant. Is that… an upside down orchid?

It is! It recently lost its blooms, but still seems to be doing pretty well.

Haha, it’s true…though Kyle inherited quite a bit from his grandpa so that definitely helped a lot.

Good question! I would love if he did a series of posts of the subject…he’s just been too busy building stuff. 😉

You guys stop being so awesome right now! I can’t take any more of your greatness! Good job as per usual. Your ideas are always so inspiring.

Currently spending my evenings designing the media cabinet for all of our records, record player, etc… Then after that, I’m thinking we should design-build a new dining room table 😉 I do have some writing ideas about process and craftsmanship, not so much from a technical aspect but emotional aspect in a sense of finding time, motivation, inspiration, to finish a project once it’s started before moving on to the next one and how to keep a project from derailing itself into a failure;)

the eileen gray c table is pretty awesome;) thanks

Amazing design! I love that it has multiple uses!

i lived in a 14 foot wide, three story, three room funky rowhouse for 17 years, and longed for a store that would sell well-considered furniture for tiny dwellings. you could make a fortune at that. one criterion is see-through chair backs, for example (your house is bigger than mine was), legs on sofas and banquettes and kitchen counters. etc., so you can see all the way through to the wall. it adds enormous amounts of visual space — and your CC table is a candidate.

And this is why I love your blog. To echo Monica, this post has it all. But, I’m a dunce, how does the smaller wood panel not fall off when it’s on it’s side? I’m sure you explained, and I just didn’t get it; I’ll go back and reread. Is it just such a tight fit? Cheers, Laura (and yes I noticed the frost on the yard! It’s getting cold . . . )

Grrr, “when it’s on its side?”

No worries, I didn’t really explain it. The smaller panel is permanently attached with screws since it doesn’t need to move. 🙂

Can we place an order for one of these?! Love the look of the wood+cork table top side by side. Form + Function. So lovely.

Way cool. I’m in constant awe of your abilities.

Hi Brooke,

Actually we are thinking about doing a small production run of these (handmade of course) as we have a few other interested people as well;) Could you e-mail Lauren @ info@chezerbey.com ? Glad you like it so much. we’ve been using it every day;)

Ok, that is just TOO awesome.

You guys are awesome. Seriously. I am amazed and so proud of both of you! Can you please come down to New Orleans and add on an extra room to our house?! Ha! Love you-

Ingenious! Good work.

awww, thanks aunt leslie, most of my projects are in remote locations so doing a residential addition/remodel in nawlins would be easy, or shoud I say “big easy”. For instance, this week I’m working on a design for a new ski cabin in Alaska and have another project under construction in Montana, just finished one up in British Columbia recently. Actually most of my projects aren’t in Seattle! So if you you want to e-mail me some information I can try and help you with a layout;)

Hey kobble :-). Don’t be surprised if I take you up on that. Lil’ O needs a playroom for all of his toys! Yikes.

I’ll be waiting;)

Pure genius.

“Hello? This is CB2. We saw your coffend table. We’d like to order 10k, deliverable next week. Thanks!”

haha, thanks Matt, our current potential order status is more like in the half dozen range;) I’m still trying to figure out how to build multiples without spending 3 weekends per table and establish a reasonable price;) I’m sure there is a solution.

I love it! Currently we are in a small space and those dual purpose items come in handy. Currently we are using our piano bench as a end table as well. Why leave the bench under an item that doesn’t get used often? Thanks for sharing.

You guys have the most complicated diys that seem simple! Great work as always. Love that you have a cat tester, they always make sure things are secure!

Hi Guys;

I’ve been following the house for a few months now thanks to some friends from OSU. We bought what appears to be a similar house 2 years ago and have slowly been working on various projects (none as extensive as yours). I am from a similar background, so while the technical aspect is great to read about, I am quite interested to hear about the “emotional” side and of some “lessons learned.” I have been notorious for lacking the discipline (mental or physical) to finish one project before the next. Although our priorities have been a moving target for one reason or another(all of which seem legitimate), we have not accomplished as much in 2 years as hoped. It would be great to hear more on this front from Kyle. Thanks for sharing. Cheers;

Wow. You guys are amazing, and bring DIY to an entirely new level. When I started reading I totally thought it was going to end with “And then we picked one up at CB2”.

HELLO ETSY TABLES!!!!

Seriously though.. how much would Kyle charge for the frame work of those tables? (I’d be willing to do the wood part myself, since i’m not sure yet what kind of wood i want to use.

price for 2… i’ll pick up next time i’m in seattle (few weeks maybe!?!)

Hmm…we’re currently looking into pricing on the frames (with and without the wood part). We’ll let you know!

Wow, very nicely done. Great ingenuity!

Um, are you two trying to give Charles and Ray a run for their money? Genius. Wish I knew someone who could make one for me.

Haha…I don’t think anyone can top the dynamic Eames duo. =)

[…] coffee table actually works a lot better in the Flex/TV room. To fill the void, we designed this table that can transform from end table to coffee table in about 10 seconds […]