One of the last big projects to tackle on the 2010 list is the loft ladder. We always knew that this would be a custom piece – not only does it have to be a precise length and angle, but it also has to serve as a guardrail at the top and bottom.

The ladder is also the first thing you see when you walk in the door, so it has to be awesome. Naturally.

We also knew that in order to be awesome, it should probably be a combination of steel and wood. We’ve been toying around with the design for the last couple of weeks and have landed on an assembly of various steel shapes (welded together), with fir wood for the treads and handrail.

As the ladder extends into the loft, the handrail goes vertical and becomes the guardrail for the lightwell below. The horizontal members here would also be a good place for apprehensive ladder climbers to grab on to. The wood treads are notched and fastened through the underside of the recessed steel plate.

Here’s a SketchUp mock-up of the whole assembly. Since we don’t have welding equipment (yet), we’re talking to a few local companies that could do the steel work and then we’d do the wood portion. Truthfully, I think Kyle is trying to decide if he wants to spend the next couple of months learning how to weld or enjoy not spending every free minute working on the house.

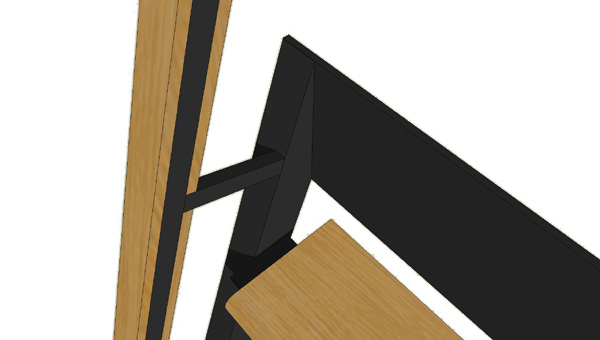

Here is a detail of the top of the stair portion – the tube steel stringers are welded to a vertical plate which gets lag screwed to a glulam beam (now covered in drywall).

The handrail would be comprised of steel bar (welded to the tube steel stringer) with a fir handrail, notched to accept the steel bar. We like the expression of the wood and steel, plus the wood is more comfortable to the touch and occurs where your hand would naturally go as you climb up the ladder.

At the bottom of the ladder, the tube steel is welded to a steel angle that gets lag screwed to the structure below and covers the edge of the cork flooring. The round bars between the treads serve as a guardrail at the bottom of the stair. (Residential building codes require a spacing tight enough that a 4″ sphere can’t pass through.) The steel tab on the left serves as a guide for the barn doors to slide by.

We also talked about doing a ship ladder (with alternating treads), but we like the relative simplicity of single treads. We’re also not sure if we would use blackened steel or have it powder-coated (maybe a dark gray). We don’t really have any other dark steel work in the house, but I think that’s ok. We’ve also gone back and forth about the finish on the barn door track and if it should match the ladder. The track comes in a galvanized (hot dipped, not electroplated) finish, which doesn’t look too bad, especially after cleaning it up a bit.

A new loft ladder will also be good motivation to actually finish the loft. After painting the rest of the main floor, I only had enough sanity to get the space primed and since then – out of sight, out of mind. I’m sure by February or so I’ll have forgotten the torture that is painting a sloped surface at awkward angles.

Just found your blog through Manhattan Nest and have been making my way through all your posts! Thanks for showing your IKEA Kitchen DIY! We are planning on tackling ours next year, and it’s great to read through all your tips!!

The ladder design looks sweet!

Thanks Mish, we’re planning on doing a post dedicated to IKEA DIY tips and tricks (once we finish the kitchen) so stay tuned for that!

Wow that design is gorgeous! You two always impress me. My husband would be all over this project. He is a machinist and does a fair amount of welding. A lot of his projects are made out of aluminum so he gets them anodized but he’s had a few of his steel pieces powder coated (they do that in shop). Plus it helps that he can order metal at cost. Too bad you didn’t live closer!

From what I know about welding (besides my husband my father in-law knows how to weld and my brother in-law is a metal artist so he does too) I’d suggest you leave this one up to the pros. It’s definitely something he could learn but how nice would the welds look? Like you said it will be a showpiece and welding is an art form.

Learning to MIG weld, which is all you really need for something like this in a mild steel, isn’t that hard. If you have a steady hand and a good tutor you can learn in a few hours. Of course this depends also on what material you are welding. If it’s mild steel square tubing with a ‘reasonable’ wall thickness, you can create some nice looking results yourself without huge effort.

However, you also need to consider that you’re going to have to cut the steel pieces to the correct dimension and then also grind/make pretty any welds that end up coming out poorly.

It’s definitely a do-able project for Kyle based on the work you guys have done on the house — seems like it’s mostly a question of how much time you want to spend on it.

Oh, and I’d probably skip the powder coating — expensive! You can get some nice textured black paint (even in a spray can) and create a fabulous finish at a very reasonable price.

Best of luck — this is truly a unique and impressive piece!

-Chris

Chris,

I actually enrolled in a MIG class today! I’ve been wanted to learn how to weld for awhile now and maybe this is the right time. We did bid the project out to a couple talented craftsman but I’m afraid it’s not in our budget right now to hire out the work so here I go. I already have a big metal chop saw, bench grinder, and drill press. Now I need a hand held grinder and welding machine. Any recommendations on a good mig welding machine? Also what’s the best type of drill bit to drill hot rolled steel? I’ve looked at cobalt, titanium nitride, and black oxide. I picked up an 1/8″ bit in each of those and plan on doing some testing.

Chris, I did take a welding class last night through http://www.teachstreet.com/metalworking/welding-for-the-diy-kind/li-48l1npaakg

It was awesome. I’m going to build this ladder.

Kyle! Sorry I didn’t get back to you sooner. I didn’t get a comment notification mail back and I didn’t think to check until now. Glad to hear that the class went well and you’re going to do this yourself. You will definitely have success — the key is to get good penetration in your welds without blowing through the material. 🙂

As far as machines go, I don’t have any real suggestions — get something that is gas shielded though if you want to get good welds with limited slag/fouling. Tell the shops you’re looking at what you’re looking to weld and go from there. Maybe a rental would be a good way to go for the short term?

Not sure about the drill bit question either — all of the welding that I have done is around assembly and modification of cars… nothing as thick as you are contemplating — nor with the original fabrication aspect.

I hope that helps a bit!

[…] January 4, 2011 by chezerbey A month ago, we showed you our design for the loft ladder. Because welding was an unknown territory for us and we didn’t own the […]

I am building a loft ladder and searching for design specs such as tread spacing , rise and run ,hand rail height ect. came across your site, like your design but please explain portion at top of handrail?Gate? would appreciate pointing me in direction of information.thank you.

[…] process. First we brainstorm ideas and sketch things out on paper. Then we test out those ideas in SketchUp. When we’re happy with the design, we detail it out in AutoCad (not always necessary, but it […]

Hi,

Loving your blog Lauren (and Kyle) since stumbling across it on a search for a loft stair / ladder solution on the Houzz website.

Here is the ‘solution’ that was gifted to this house about 13 years ago by two owners previous to us: http://victorianhouseproject.blogspot.co.uk/2011/09/konni-sees-red-no-more.html.

Yep, it’s an off-the-peg number that has been twisted off-centre into the space, with the bottom tread sticking out over the landing and the weight being taken by just one of the two bolts at the base – the other is screwed into the edge of a piece of wood and, er, nothing, i.e. the air. Despite us putting the rails back on this thing, it is still a long way down to the bottom of the ground floor stairs.

We were wondering whether your beautiful and practical ladder could be a way forward for the tiny space we have. The ‘solid’ floor available is 0.75m by 1.03m, going up to a ceiling opening that is 0.875m by 1.39m. The height from floor to floor is 2.86m. This place is also the only way to get up to the loft without having to do so from one of the bedrooms.

Wishing you festive cheer, and hoping that you or some of your clever readers can help (NB. we are exploring other options).